Choosing the Best Company for Your litho printing Needs

Choosing the Best Company for Your litho printing Needs

Blog Article

A Comprehensive Overview to Recognizing Litho Printing Strategies

The globe of litho printing, a method originating from the late 18th century, is a fascinating blend of background, advancement, art and science. This thorough guide will certainly unravel the intricacies of this printing technique, from the structure of litho inks to the obstacles dealt with in contemporary applications. As we venture right into the details of lithography, the relevance of automation and sustainability in ensuring its future relevance ends up being increasingly clear. Remain with us as we journey right into the captivating realm of litho printing.

The Historical Evolution of Litho Printing

The historical trajectory of litho printing, a crucial innovation in the world of interaction, is an exciting tale of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this method was at first a cost-effective method of releasing staged jobs. Lithography, originated from the Greek words for 'rock' and 'to compose', made use of a smooth rock surface to move pictures onto paper. The process advanced with the introduction of the rotary press, which considerably increased productivity (litho printing). In the 20th century, the technology of balanced out lithography changed the sector, allowing for automation of premium prints. Each phase of litho printing's advancement showcases humankind's ruthless pursuit of performance and top quality in visual interaction.

Deciphering the Science Behind Litho Printing Inks

Progressing in the expedition of litho printing techniques, the focus currently moves to the science behind litho printing inks. The structure of these inks, their drying procedure, and color mixing methods form the backbone of this complex art form. Comprehending these elements is important to grasping the craft and attaining the wanted print outcomes.

Composition of Litho Inks

In lithographic printing, the essential role of litho inks can not be overemphasized. Pigments, the color-providing aspects, are carefully ground fragments put on hold in the car, a liquid that brings the pigment onto the printing surface. Each component plays a crucial component in the last print's top quality, making the accurate formulation of litho inks a complex scientific research.

Ink Drying Process

From the make-up of litho inks, focus turns to the interesting procedure of ink drying out. 2 primary methods are made use of in litho printing: oxidative drying out and absorption. Absorption, on the various other hand, entails the ink permeating into the paper fibers, which is a quicker process yet can lead to much less lively colors.

Shade Combining Techniques

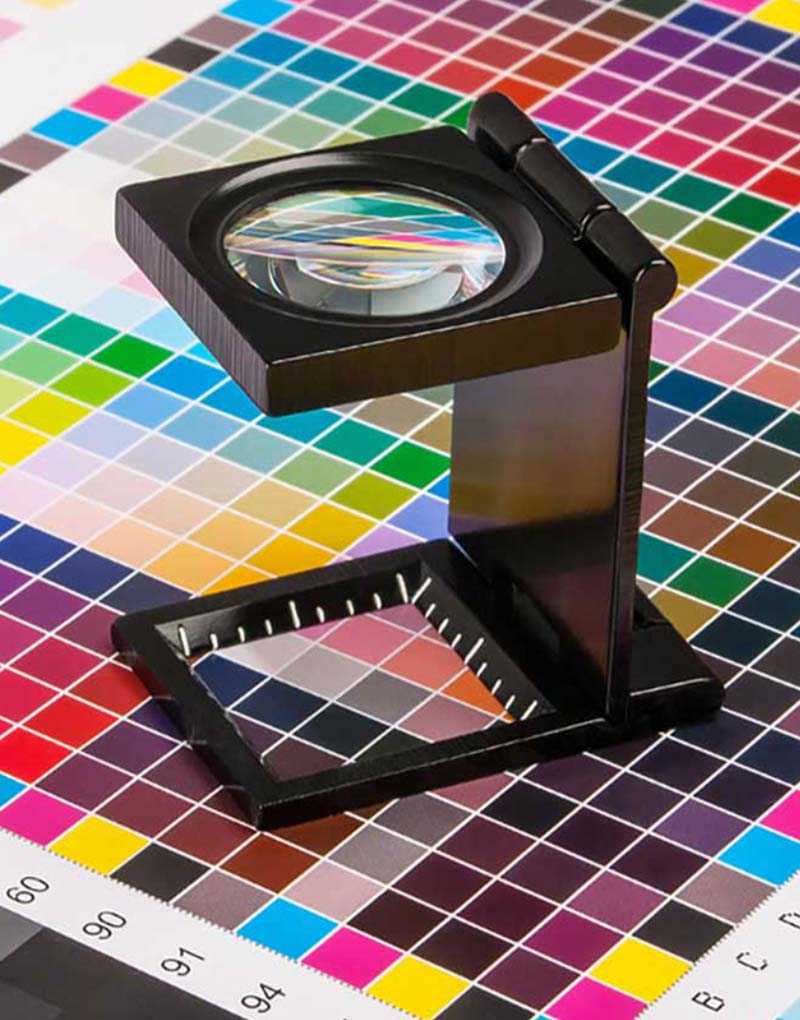

While the drying procedure plays a crucial role in litho printing, the scientific research of shade blending methods holds equal importance. This is an intricate process that involves the careful mixing of main shades: cyan, magenta, and yellow, in varying proportions to achieve a vast selection of shades. The enhancement of black ink, referred to as 'crucial', assists in regulating the strength and deepness of the colors. The scientific research behind litho printing inks likewise thinks about the openness of the ink, which affects just how colors overlay and mix. To accomplish an efficient shade mix, print experts have to also understand the intricacies of ink actions, color theory, and the physical buildings of the substrate on which the ink is used.

The Art and Style Elements in Litho Printing

Litho printing breathes life right into art and layout with its special components. The procedure includes producing a picture on a Our site lithographic limestone plate or metal plate with a smooth surface. The photo is then published onto a medium, normally paper, by transferring the ink from the plate. What sets litho printing apart is its ability to replicate detailed layouts with high fidelity, making the outcome nearly identical to the original artwork. This is attained via using various line strategies such as cross-hatching, hatching, and stippling, which permit a variety of tonal impacts. Litho printing accommodates a range of colors, allowing musicians to develop vibrant and vibrant prints. This mix of precision and adaptability makes litho printing a favored selection for several artists and developers.

Modern Applications of Litho Printing Methods

Litho printing strategies have located comprehensive usage in the modern-day business field. Its influence and importance proceed to expand with the introduction of new developments and innovations in the area. This area will certainly check out these modern applications and the transformative role they play in the printing industry.

Business Litho Printing Uses

In today's digital age, one may question the relevance of traditional printing techniques. Yet, litho printing continues to be a critical component of the industrial sector. High-volume printing tasks, such as the manufacturing of books, papers, and packaging, depend on litho printing for its ability to supply remarkable picture top quality and price performance. The procedure, which entails transferring an inked image from a plate onto a rubber covering and after that to the printing surface, provides unparalleled consistency. This makes it suitable for work needing a big print run. Litho printing likewise offers a wide shade spectrum, above that of digital printing. This makes it the best selection for tasks that require vibrant, top notch color recreation.

Developments in Litho Printing

Pressing the borders of standard strategies, contemporary innovations have fueled a host of technologies in litho printing. One popular growth is digital litho printing, which incorporates the merits of electronic modern technology with litho's high-quality outcome. These developments underscore the long-lasting relevance of litho printing in the modern globe.

Exploring the Refine of Litho Printing: Detailed

Difficulties and Solutions in Contemporary Litho Printing

Regardless go of the precision and tradition that litho printing proudly promotes, it is not without its set of modern difficulties. Digital litho printing allows for economical short runs and very easy personalization, attending to the concern of variable data. Therefore, while there are challenges, the litho printing market is proactively adapting to meet them head-on, guaranteeing its importance in the future.

Verdict

Finally, litho printing, with its abundant background and scientific intricacies, holds a substantial location in the print sector. As the overview reveals, it's a synthesis of art and innovation, with modern-day improvements ensuring its relevance. The sector faces challenges that call for ingenious solutions, with a focus on automation and sustainability. The future of litho printing rests on its ability to adapt to these transforming needs, affirming its enduring value in an advancing market.

Report this page